When producing plastic bottle preforms, the quality requirements for PET (Polyethylene Terephthalate) resin are extremely stringent, as the raw material properties directly determine the preform’s moldability, clarity, mechanical strength, and safety of the final product. Below are the key specifications:

1. Intrinsic Viscosity (IV Value)

- Range: Typically 0.70–0.85 dl/g. IV affects mechanical strength and pressure resistance:

- Low IV (0.70–0.75): Suitable for short injection cycles but results in weaker preforms.

- High IV (0.80–0.85): Enhances pressure resistance (e.g., for carbonated beverage bottles).

- Testing: Measured via Ubbelohde viscometer or melt flow rate (MFR) analysis.

2. Moisture Control

- Requirement: Moisture content must be ≤0.005% (50 ppm).

- Rationale: PET is hygroscopic and prone to hydrolysis at high temperatures, leading to chain scission, IV drop, and brittle preforms.

- Drying: Resin must be dried at 150–180°C for 4–6 hours before processing.

3. Crystallinity & Melting Point

- Melting Point: High-quality PET melts at 250–260°C.

- Crystallinity: Amorphous PET is preferred to avoid crystallization-induced defects (e.g., whitening) during injection molding.

4. Chemical Purity

- Acetaldehyde (AA): Must be ≤3 ppm (food-grade) to prevent flavor contamination.

- Oligomer Residues: Controlled via extraction to avoid haze or mold contamination during processing.

- Catalyst Residues: Antimony (Sb) content must comply with FDA limits (≤0.5 ppm).

5. Thermal Stability

- Processing Temperature: Maintained at 270–290°C to prevent thermal degradation (e.g., gas formation, black specks).

- Stabilizers: Phosphite-based additives may be used to extend melt stability.

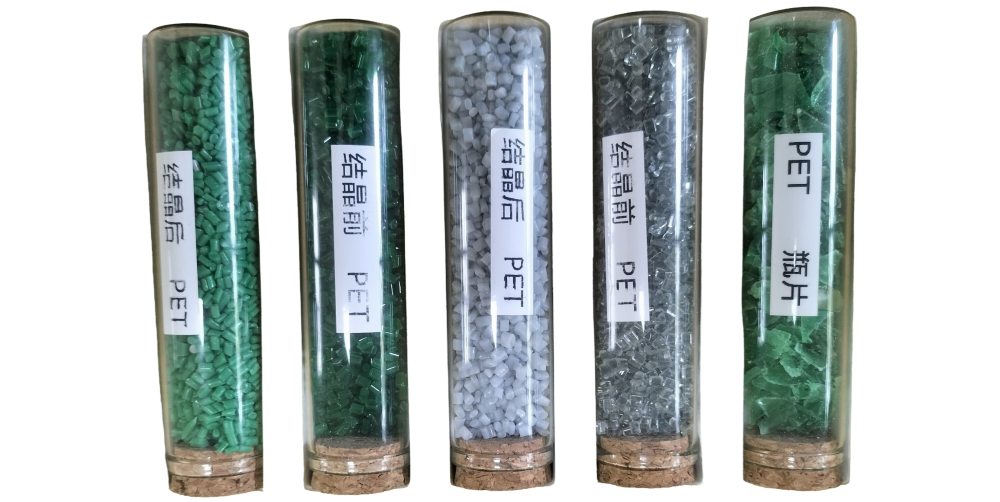

6. Appearance & Clarity

- Color Metrics: L-value ≥80 (lightness) and b-value ≤2 (yellowness) for optical clarity.

- Contaminants: No black spots, foreign particles, or unmelted granules; achieved via melt filtration (≤20μm filters).

7. Food-Grade Compliance

- Regulations: Must meet FDA 21 CFR 177.1630 (U.S.) or EU 10/2011 (Europe) for food-contact materials.

- Testing: Includes heavy metal migration, total migration, and AA release.

8. Requirements for Recycled Material (rPET) Usage

- Purity: rPET must be free of contaminants (e.g., PVC, PLA) and typically limited to ≤30% (brand-dependent).

- IV Restoration: rPET often requires Solid-State Polycondensation (SSP) to boost IV to acceptable levels.

9. Processing Performance

- Melt Flow: Must align with mold design to prevent short shots or flash.

- Shrinkage: Uniform shrinkage (longitudinal ≤1.5%) ensures dimensional consistency.

Common Defects Linked to Resin Quality

- Yellowing: Caused by thermal degradation or insufficient drying.

- Neck Cracking: Low IV or excessive moisture-induced chain breakage.

- Haze: Impurities or high crystallinity.

Summary

PET resin selection requires balancing IV, moisture, thermal stability, and regulatory compliance. Rigorous incoming inspections (e.g., DSC for melting point, Karl Fischer titration for moisture) are critical. Reputable suppliers (e.g., Indorama, Far Eastern New Century) are recommended for bottle-grade PET chips, with regular batch consistency checks.