PET preforms are used to make plastic bottles, but making them can have many problems. Issues like bad materials, wrong machine settings, poor mold design, or workshop conditions can hurt quality. Fixing these problems is key to making strong, clear PET preform. This article explains common defects in PET preform production, their causes, and simple solutions.

1. Material Problems

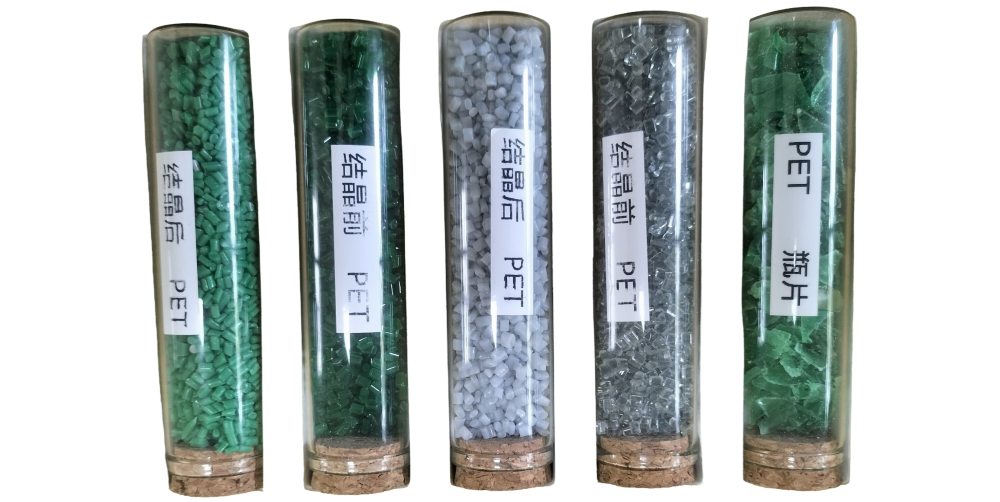

PET resin must be clean and dry. First, PET absorbs moisture easily. If not dried enough (moisture should be below 0.005%), bubbles or silver streaks form when melted. Also, dirty or old bits of plastic can create black spots or make preforms look cloudy.More information please read: Key PET Resin Requirements for Plastic Bottle Preform Manufacturing

Using too much recycled PET saves money but weakens the preform. It may cause cracks, uneven walls, or poor heat resistance.

2. Machine Setting Mistakes

Wrong temperatures or pressures cause most defects. For example:

- Too hot (over 290°C): PET breaks down, turning yellow or burnt.

- Too cold (under 260°C): Plastic doesn’t flow well, causing gaps or rough surfaces.

- Uneven mold temps: Parts cool differently, making some areas cloudy or weak.

Also, low injection pressure leaves empty spaces in the mold. Too little cooling time causes dents or stress cracks later.

3. Mold Design Flaws

Poor mold design creates defects:

- Bad gate design: If the gate (where plastic enters the mold) is poorly placed, lines or air bubbles form.

- Weak cooling: Bad cooling channels take longer to cool the preform, causing warping or uneven shrinkage.

- Trapped air: Without proper vents, gas burns leave dark marks on the preform.

4. Machine and Human Errors

Old or broken machines cause issues:

- Worn screws mix dirty or burnt plastic into melts.

- Loose molds create flash (extra plastic edges).

Workers can also make mistakes:

- Wrong settings for temperature or pressure.

- Not cleaning molds regularly.

- Skipping maintenance checks.

5. Workshop Conditions

- Humidity: Wet air makes dried PET resin damp again.

- Power issues: Voltage drops or machine shakes ruin consistency.

Key Defects to Avoid

- Bubbles/Silver streaks: Dry resin properly.

- Black spots: Filter materials and clean machines.

- Weak walls: Check injection pressure and mold cooling.

- Cracks: Avoid fast cooling and fix mold alignment.

How to Fix These Issues

- Dry PET resin fully before use.

- Control temperatures: Keep melts between 260–290°C.

- Design molds carefully: Focus on gate placement, cooling, and vents.

- Check machines often: Replace worn parts and clean molds.

- Train workers: Teach proper settings and safety steps.

By solving these problems, factories can make strong, clear PET preforms for high-quality bottles.